Featured Products

-

- Cast Embossed Film LineThe cast film line produces flat or embossed films for hygiene, medical and packaging applications by using LDPE, LLDPE, HDPE, PP or EVA as raw materials.See Full Product Info

-

- Multi-layer Cast Film LineOur multi-layer cast film line uses co-extrusion to optimize film performance for hygiene, medical and packaging application by using LDPE, LLDPE, HDPE, PP, and EVA.See Full Product Info

-

- 3-layer CPP Film LineThe CPP cast film line is used to produce high-quality cast polypropylene film (CPP film) for a wide range of packaging applications.See Full Product Info

-

- Cast Perforated Film LineThe cast film line produces micro-perforated film by using the materials of polyethylene. While the melt resin comes out of extrusion die, it is formed into film... See Full Product Info

-

- Cast Breathable Film LineThe extruder structure is changed to multi-layer co-extrusion. The multi-layer co-extrusion method helps to greatly increase the extrusion output, and the resins blending is more uniform.See Full Product Info

-

- PETG Shrink Film Extrusion LineWellson Machinery provides customers with customized PETG turnkey equipment production lines including extruders, casting unit, MDO unit and winders.See Full Product Info

-

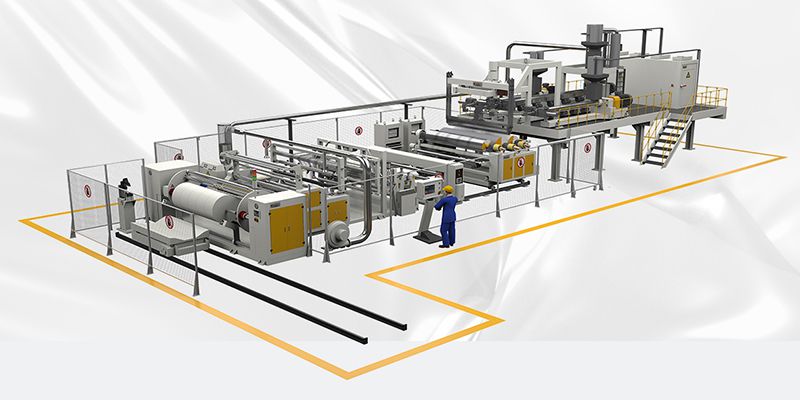

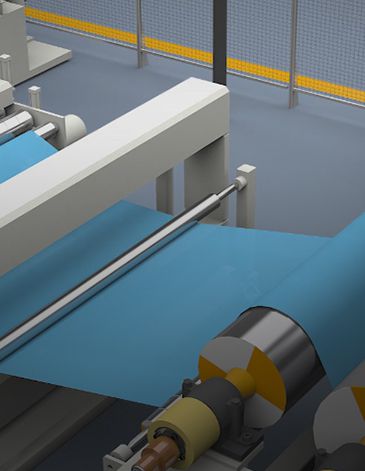

- Extrusion Coating Laminating Line for NonwovenNonwoven extrusion coating laminating line is equipped with high-performance extruder, chrome-plated chill roll, and fully-auto unwinder and winder.See Full Product Info

-

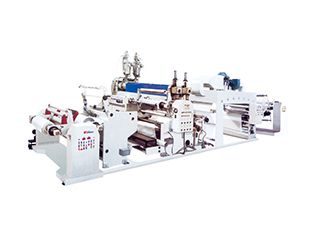

- Extrusion Coating and Laminating Line for Flexible PackagingBy such a converting process, we are able to deliver a high-performance packaging materials for a variety of applications.See Full Product Info