Stone Paper Production Line

- Printed materials: notebook, envelop, business card, poster, map, manuals, calendar, labels and tags etc.

- Packaging product: wrapping paper, packing bag, packing box, etc.

- Decorated paper: wall paper

- Disposable goods: garbage bags, disposal tablecloth, shopping bag, food wrap bag, etc.

| Model No. | Product Width | Product Thickness | Output per Hour | Installed Power |

| WS120/90-2200 | 1400mm | 0.03-0.30mm | 500-800kgs | 600kW |

| WS150/110-3000 | 2200mm | 0.03-0.30mm | 800-1500kgs | 850kW |

| WS180/150-4000 | 3200mm | 0.03-0.30mm | 1000-2000kgs | 1000kW |

* Remarks: Machine dimensions can be customized upon request.

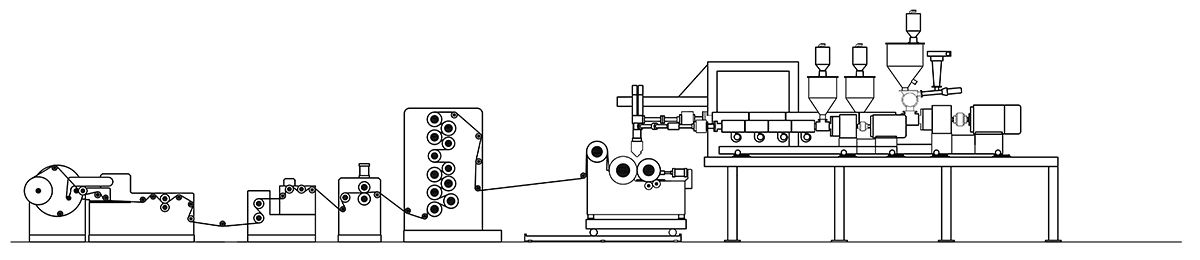

- Equipped with in-line CaCo3 compounding, the line can use CaCo3 powder directly, and save great power consumption.

- Much higher output capacity than those traditional machines.

- Avoid the problem of CaCo3 powder release

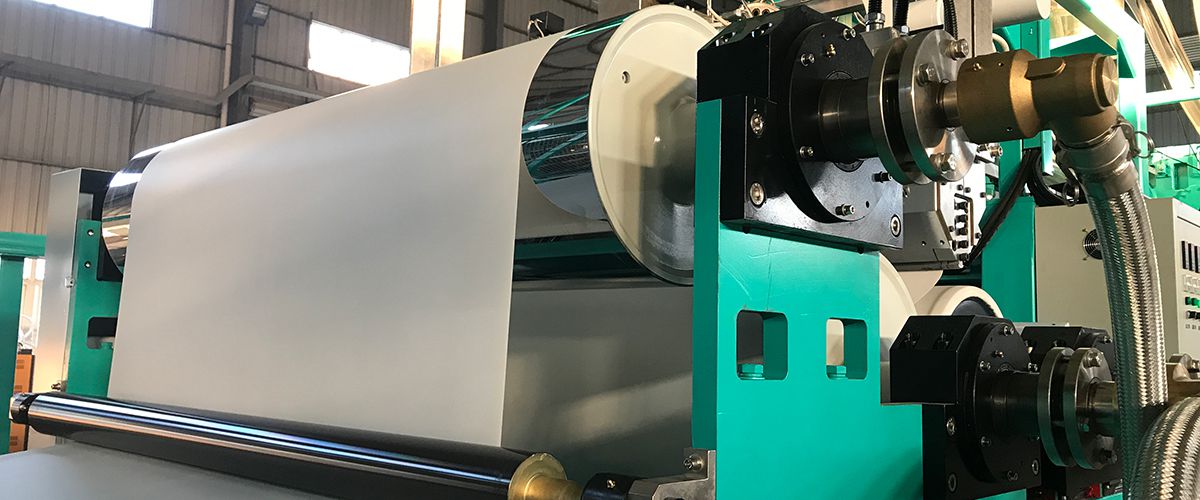

The stone paper is a kind of synthetic paper of which the production process is grinding the stone into powder and then cementing the powder with PP or PE. The main ingredients of the stone paper is CaCO3. Compared with the traditional wood pulp paper, the production of the stone paper requires no water so the production process is extremely environment friendly. Meanwhile, the stone paper can be replacement of the traditional paper in many fields. It is a latest product which is widely praised.

There are three steps in the production of the stone paper: pelleting, base paper production and paper coating. Among these three steps, the base paper production is the key one. Our equipment adopts the process of tape casting for production. And it can provide best products performance via MDO vertical stretching.

We offer the turn-key project for stone paper production, supplying full equipment, transferring know-how and training operators.