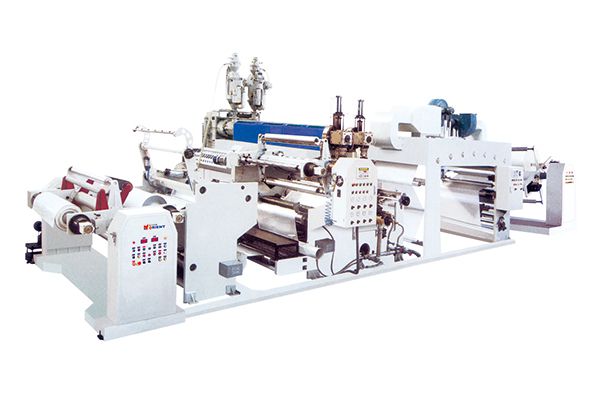

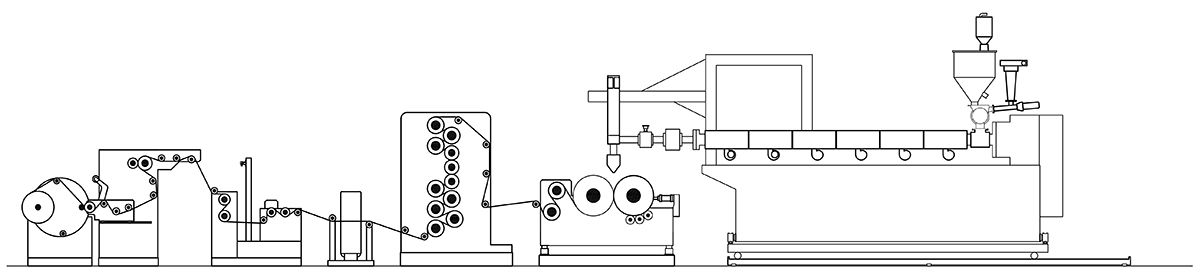

Cast Breathable Film Line, Breathable Film Machine

Breathable film is growingly used in those fields such as baby diaper, sanitary napkin, medical dressings, and waterproof membrane for roof underlay.

| Model No. | Screw Dia. | Die Width | Film Width | Film Thickness | Line Speed |

| FMB135-2300 | 135mm | 2300mm | 1600mm | 0.02-0.20mm | 250m/min |

| FMB150-2800 | 150mm | 2800mm | 2200mm | 0.02-0.20mm | 250m/min |

| FMB180-3600 | 180mm | 3600mm | 3000mm | 0.02-0.20mm | 250m/min |

* Remarks: Machine dimensions can be customized upon request.

- Oil heating system for MDO unit

- MDO unit with horizontal stretching

- On-line deep embossing is optional.

- In-line lamination with nonwoven is optional

Breathable film line has the same extrusion process as other cast film lines, but equipped with the MDO (machine direction orientation) unit. Filled with appr. 50% percentage of CaCo3, the film is stretched by MDO unit to make micro pores inside. Those high-density micro pores in the film allow the gas or water vapor to transmit but stop the liquid flow. So it gets the name as "breathable film". Its outstanding features not only can be found in "breathable", but also in textile-like hand feeling, making it an ideal backsheet for diaper and sanitary napkin.

The heat transfer oil heating method has good heat transfer performance and low energy consumption, which can make the MDO film stretching more uniformly heated and increase the tensile force of film products. The extruder structure is changed to multi-layer co-extrusion. The multi-layer co-extrusion method helps to greatly increase the extrusion output, and the resins blending is more uniform. The product quality is better.

Breathable film is used in the medical and health care products. It has the characteristics of breathability and waterproof, which can increase the comfort of the human body and achieve the effect of isolating viruses and bacteria.