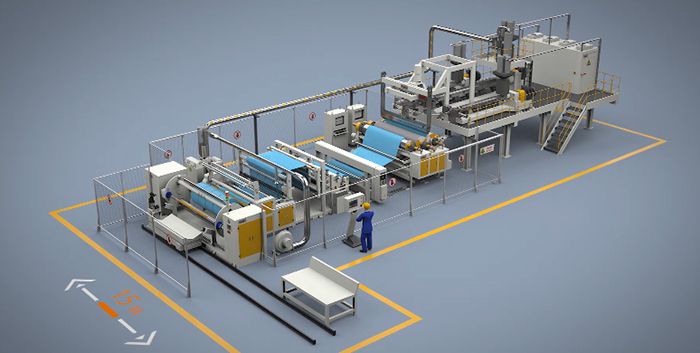

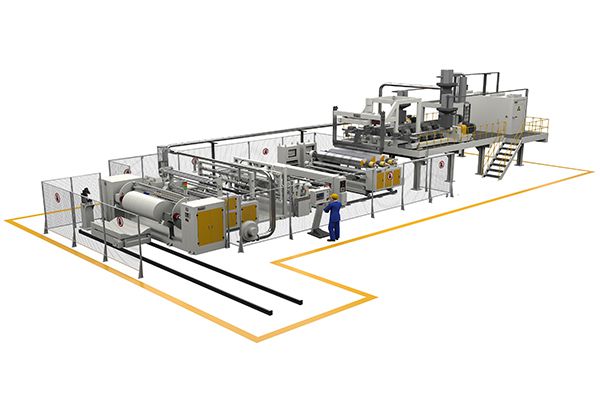

Cast Film Extrusion Line

To meet customer's specific requirement, we provide a variety of complete cast film extrusion lines from 1000mm-wide monolayer line to 7-layer barrier film line, and as well as the tailored production line. The advanced technology and smart manufacturing technique are brought into the production line, including extruder, flat T die, chill roll, winder and other downstream parts. The extruder and flat T die, which are two optimized designs, guarantee high performance and various features of the line. Additionally, automation can be achieved to satisfy the customers' requirements.

-

- Cast Embossed Film Line The cast embossed process has a wide range of applications, such as PE film for baby diaper, sanitary napkin, inconvenience products, pet pad, disposable bed sheet, medical dressings, grown, gloves, shoes cover, rubber release film, table cloth, shower curtain, and so forth.

-

- Multi-layer Cast Film LineThe multi-layer co-extrusion process is used to produce hygiene films, CPP film, stretch film, cling film, masking film, agricultural films, medical films, barrier films for packaging food such as meats, snack, bakery, frozen foods, and so forth.

-

- CPE Cast Film LineCPE cast film line is well designed to produce transparent cast polyethylene film (CPE film). Equipped with auto thickness controlling system and efficient chill roll, the line produces CPE film of good transparency and low gauge variation, ideal for laminating and surface protection.

-

- 3-layer CPP Film LineThe CPP cast film line is used to produce high-quality cast polypropylene film (CPP film) for a wide range of packaging applications. Equipped with auto thickness controlling system and efficient chill roll, the line produces CPP film of high transparency and very low gauge variation, ideal for laminating and metalizing.

-

- EVA/PEVA Cast Film LineThe line is well designed to produce EVA and PEVA films for various applications. The most optimized design of extruder and T die guarantees high-performance extrusion and various levels of features and automation are available to best meet your needs.

-

- TPU Cast Film LineTPU cast film line is well designed to produce TPU hot melt film, TPU laminating film and highly transparent TPU film. The line accept both high-temperature and low-temperature TPU resins, and it can run different types of TPU film products.

-

- Cast Perforated Film LineThe cast film line produces micro-perforated film by using the materials of polyethylene. While the melt resin comes out of extrusion die, it is formed into film and vacuum perforated at the same time. Those micro-holes have features of 3-dimensional , uniform and funnel shape, which keeps air and water permeable with very low revert.

-

- Barrier Cast Film LineThe barrier film line uses automatic T die with edge encapsulation technology for cost-efficiency, which allow the recycling of edge trim. Besides barrier film, the line is versatile for producing CPP film and CPE film, which create great flexibility for you.

-

- PLA, PHA Biodegradable Film Extrusion Line The application of PLA, PHA biodegradable film has changed the characteristics of traditional plastic film; film products can be degraded under the action of sunlight, and are easily digested by the environment when they are disposed of.

-

- EVA/POE Solar Film Extrusion LineSolar panel encapsulation film extrusion line takes EVA and POE as raw materials. The process includes materials handling, heating, extruding, calendaring, cooling and winding. The production line can be specially made by customer’s requirements.

-

- Stretch Film Extrusion LineThe raw material is mainly LLDPE, blended with some other resins such as mLLDPE. The co-extruded stretch wrapping film of 3 or 5 layers has excellent tensile strength and resistance to puncture and impact, thus making it an ideal wrapping both manually and mechanically to protect pallet or other goods during transportation.

The cast film extrusion line is equipped with particular screw and barrel. The special mixing screw guarantees the complete plasticization and stable extrusion of the raw material. The barrel with the air-cooled heater, offers good heat transmission and dispersion. Since the extrusion die head is the top brand in the world, it has a long lifespan and ensures the uniform thickness of the film. The full-automatic adjustable die head and the automatic thickness gauge can also be adopted to detect the film thickness on-line and make adjustment accordingly.

The chill roll of the cast film extrusion line is helical channel roll of large diameter, offering better chill effect. The advanced full-automatic film winding system can cut and change film rolls automatically, enabling crease-free roll and neat ends. Moreover, the direct on-line recycle of film offcut greatly reduces the production cost.

The whole extrusion line is under the control of PLC, with human-computer interface, which simplifies the process and helps the maintenance of the equipment. The electric apparatuses adopted come from top brand products such as Siemens, ABB and Mitsubishi, etc. Therefore, they are reliable and get easy access to the after-sale service.

Orient Machinery is a specialized cast film extrusion line manufacturer in China. Our company offers a vast range of products, including cast embossed film line, monofilament extrusion line, extrusion coating machine and more.