-

- Cast Embossed Film Line The cast film line produces flat or embossed films for hygiene, medical and packaging applications by using LDPE, LLDPE, HDPE, PP or EVA as raw materials. The most optimized design of extruder and T die guarantees high-performance extrusion, and various levels of features and automation are available to best meet your needs.

-

- Multi-layer Cast Film LineOur multi-layer cast film line uses co-extrusion to optimize film performance for hygiene, medical and packaging application by using LDPE, LLDPE, HDPE, PP, and EVA. The lines offer many options, such as 2-layer, 3-layer, and 5-layer film coextruded structure. The number of co-extrusion layers depends on the market need.

-

- CPE Cast Film LineCPE cast film line is well designed to produce transparent cast polyethylene film (CPE film). Equipped with auto thickness controlling system and efficient chill roll, the line produces CPE film of good transparency and low gauge variation, ideal for laminating and surface protection. 3-layer CPE film is the most popular in the market.

-

- 3-layer CPP Film LineThe CPP cast film line is used to produce high-quality cast polypropylene film (CPP film) for a wide range of packaging applications. Equipped with auto thickness controlling system and efficient chill roll, the line produces CPP film of high transparency and very low gauge variation, ideal for laminating and metalizing.

-

- EVA/PEVA Cast Film LineThe line is well designed to produce EVA and PEVA films for various applications. The most optimized design of extruder and T die guarantees high-performance extrusion and various levels of features and automation are available to best meet your needs.

-

- TPU Cast Film LineTPU cast film line is well designed to produce TPU hot melt film, TPU laminating film and highly transparent TPU film. The line accept both high-temperature and low-temperature TPU resins, and it can run different types of TPU film products.

-

- Cast Perforated Film LineThe cast film line produces micro-perforated film by using the materials of polyethylene. While the melt resin comes out of extrusion die, it is formed into film and vacuum perforated at the same time. Those micro-holes have features of 3-dimensional , uniform and funnel shape, which keeps air and water permeable with very low revert.

-

- Barrier Cast Film LineEVOH high-barrier film is one of the most widely used high-barrier materials. There are also heat-resistant types for aseptic packaging products. The barrier properties of EVOH high barrier films depend on the ethylene content. Generally speaking, when the ethylene content increases, the gas barrier properties decrease, but it is easy to process.

-

- PLA, PHA Biodegradable Film Extrusion Line The application of PLA, PHA biodegradable film has changed the characteristics of traditional plastic film; film products can be degraded under the action of sunlight, and are easily digested by the environment when they are disposed of.

-

- EVA/POE Solar Film Extrusion LineSolar panel encapsulation film extrusion line takes EVA and POE as raw materials. The process includes materials handling, heating, extruding, calendaring, cooling and winding. The production line can be specially made by customer’s requirements. The film product is a new type of thermosetting hot melt film, anti-adhesive at normal temperature, easy for operation.

-

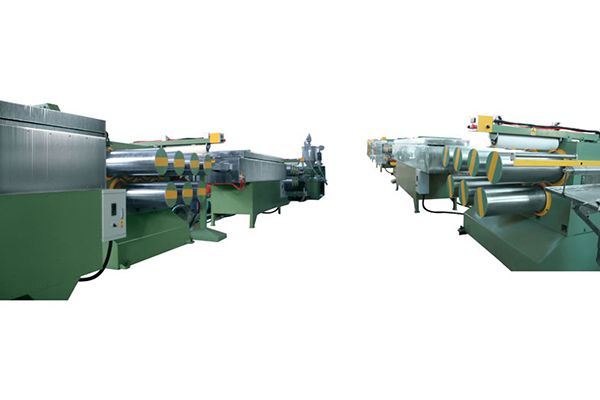

- Stretch Film Extrusion LineThe raw material is mainly LLDPE, blended with some other resins such as mLLDPE. The co-extruded stretch wrapping film of 3 or 5 layers has excellent tensile strength and resistance to puncture and impact, thus making it an ideal wrapping both manually and mechanically to protect pallet or other goods during transportation.

-

- MDO UnitFilms being stretched by MDO have a wide range of applications such as breathable film for baby diaper and roofing membrane; stone paper or synthetic film; PETG shrink film, barrier film, CPP & CPE film for flexible packaging; as well as film for adhesive tapes, labels, etc.

-

- Cast Breathable Film LineBreathable film line has the same extrusion process as other cast film lines, but equipped with the MDO (machine direction orientation) unit. Filled with appr. 50% percentage of CaCo3, the film is stretched by MDO unit to make micro pores inside.

-

- PETG Shrink Film Extrusion LineWellson Machinery provides customers with customized PETG turnkey equipment production lines including extruders, casting unit, MDO unit and winders. In addition, our company also provides resin processors, thickness gauges, corona treater and edge trimmers for PETG film production line.

-

- Stone Paper Production LineThe stone paper is a kind of synthetic paper of which the production process is grinding the stone into powder and then cementing the powder with PP or PE.

-

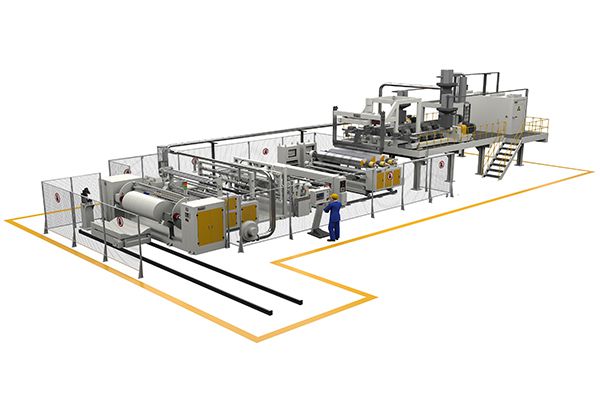

- Extrusion Coating Laminating Line for NonwovenNonwoven extrusion coating laminating line is equipped with high-performance extruder, chrome-plated chill roll, and fully-auto unwinder and winder. The extruder coats PE polymer materials onto a substrate of nonwoven fabric and makes nonwoven composite without using any glue.

-

- Extrusion Coating Lamination Line for PaperPE extrusion coating line has the advantages of high degree of automation, easy operation, high production output, and uniform coating thickness. The coated paper product has high adhesion fastness, clear-cut edge winding, environmental protection and no pollution.

-

- Extrusion Coating Laminating Line Woven FabricWoven fabric extrusion coating line is equipped with high-performance extruder, chrome-plated chill roll, and high tension control system. The extruders coat PE polymer resins onto a substrate of woven fabric and make the high bonding strength between melt curtain and woven fabric substrate.

-

- Extrusion Coating and Laminating Line for Flexible PackagingIn extrusion coating and laminating, the resins, melted and formed into a hot thin film, is joined with the substrate materials like paper, PET film or aluminum foil. By such a converting process, we are able to deliver a high-performance packaging materials for a variety of applications.

-

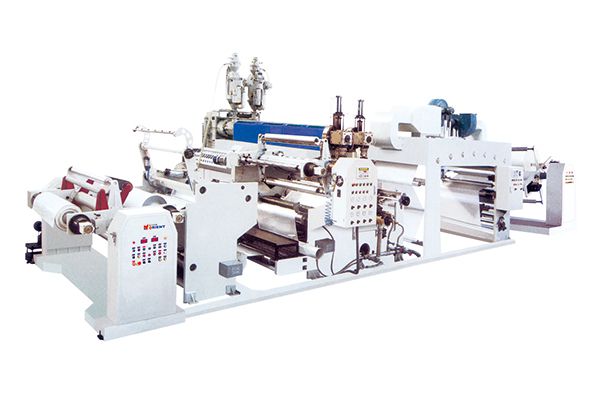

- Hot Melt Glue Laminating & Coating MachineHot melt glue laminating and coating machine is mainly composed of hot melt glue spray, servo motor-controlled winder and unwinder, servo motion controller, servo automatic rectifying system and human-computer interface control, etc.

-

- By using raw materials of PET, PA, PE and PP, the monofilament extrusion line is provided for lots of applications such as brush, broom, fishing line and net, ropes, sewing and zipper thread, ect. The monofilament production process mainly follows the steps of extrusion, forming, stretching, heat setting and winding.

Fujian Wellson Machinery Co., Ltd. is located in the city of Quanzhou, a major industrial town in China. We specializes in developing and manufacturing the complete lines of thermoplastic machinery. Our innovative technology and extensive experiences contribute to building cast embossed film line, CPP film line, stretch film line, perforated film line, breathable film line, barrier film line, EVA / PEVA cast film line, TPU cast film line, extrusion coating and lamination line and monofilament extrusion line. Being reliable, durable and priced reasonably, our equipment dominate the domestic market and have been widely accepted worldwide.