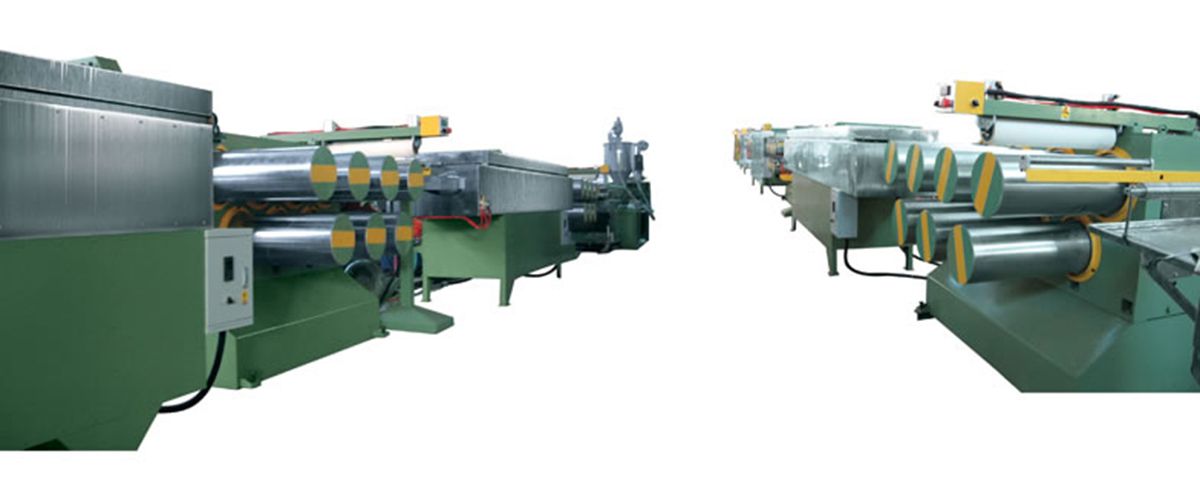

Monofilament Extrusion Line

Technical Parameters

| Model No. | SJ65 | SJ75 | SJ90 |

| Screw Diameter | Ф65mm | Ф75mm | Ф90mm |

| Screw L/D | 1:33 | 1:33 | 1:33 |

| Die Diameter | 160mm | 200mm | 200mm |

| Extrusion Capacity | max 60kg/h | max 80kg/h | max 250kg/h |

| Monofilament Dia. | 0.10-2.0mm | 0.10-2.0mm | 0.10-2.0mm |

| Installed Power | Appr. 150kw | Appr.180kw | Appr.240kw |

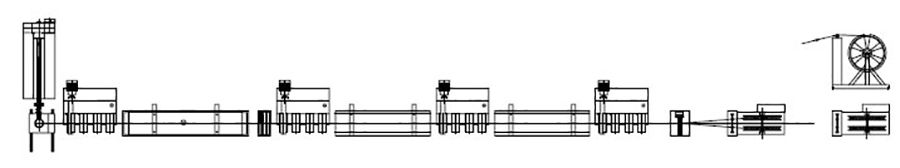

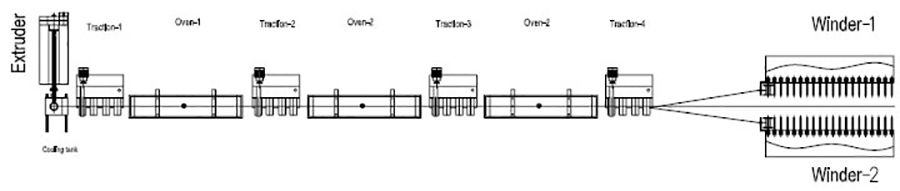

Line Layout

By using raw materials of PET, PA, PE and PP, the monofilament extrusion line is provided for lots of applications such as brush, broom, fishing line and net, ropes, sewing and zipper thread, ect. The monofilament production process mainly follows the steps of extrusion, forming, stretching, heat setting and winding.

To meet various needs of end-use products, different winding systems are then offered. Flange winder is more often used for making brush and broom, bobbin winder is frequently applied for textile such as sewing thread; and spool winder is crucial for producing fishing line. Therefore, the monofilament extrusion line is popular for its user-friendly operation and reliable performance.

Get in Touch

Fujian Wellson Machinery Co., Ltd. is located in the city of Quanzhou, a major industrial town in China. We specializes in developing and manufacturing the complete lines of thermoplastic machinery. Our innovative technology and extensive experiences contribute to building cast embossed film line, CPP film line, stretch film line, perforated film line, breathable film line, barrier film line, EVA / PEVA cast film line, TPU cast film line, extrusion coating and lamination line and monofilament extrusion line. Being reliable, durable and priced reasonably, our equipment dominate the domestic market and have been widely accepted worldwide.