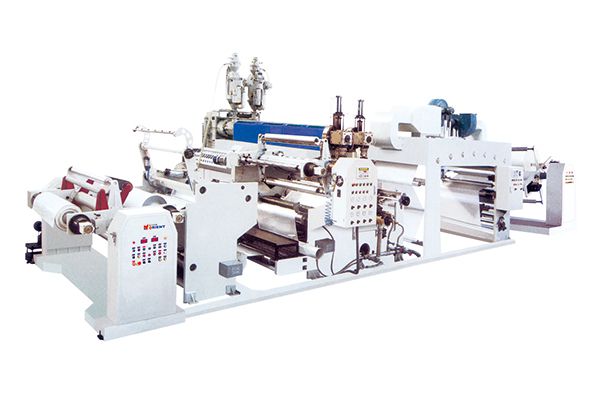

Coating and Laminating Line

Besides the cast film extrusion lines, the compound production line is also provided. There are two options available for the coating and laminating line, including heat coating and laminating and hot melt glue laminating. The customers can make their own choice according to the requirements of the end-use products.

-

- Extrusion Coating Laminating Line for NonwovenNonwoven extrusion coating laminating line is equipped with high-performance extruder, chrome-plated chill roll, and fully-auto unwinder and winder. The extruder coats PE polymer materials onto a substrate of nonwoven fabric and makes nonwoven composite without using any glue.

-

- Extrusion Coating Lamination Line for PaperPE extrusion coating line has the advantages of high degree of automation, easy operation, high production output, and uniform coating thickness. The coated paper product has high adhesion fastness, clear-cut edge winding, environmental protection and no pollution.

-

- Extrusion Coating Laminating Line Woven FabricWoven fabric extrusion coating line is equipped with high-performance extruder, chrome-plated chill roll, and high tension control system. The extruders coat PE polymer resins onto a substrate of woven fabric and make the high bonding strength between melt curtain and woven fabric substrate.

-

- Extrusion Coating and Laminating Line for Flexible PackagingIn extrusion coating and laminating, the resins, melted and formed into a hot thin film, is joined with the substrate materials like paper, PET film or aluminum foil. By such a converting process, we are able to deliver a high-performance packaging materials for a variety of applications.

-

- Hot Melt Glue Laminating & Coating MachineHot melt glue laminating and coating machine is mainly composed of hot melt glue spray, servo motor-controlled winder and unwinder, servo motion controller, servo automatic rectifying system and human-computer interface control, etc.

As for the heat coating line, it actually refers to an extrusion coating by coating a substrate with the melt resin coming from extrusion die. The process is running at high speed free from solvent and adhesive. Additionally, various thicknesses of coating can be achieved to satisfy the requirements of the customers. The extrusion coating line is equipped with the following important parts, including extruder, T die, chill roll & press roll, unwinder & rewinder. The cutting-edge technology and extensive experience in cast film line enable us to produce extrusion coating line of high quality as well.

The hot melt glue laminating machine features with its high cost-efficiency since the precise process ensures adequate use of glue adhesive without waste. Moreover, it is reliable and enduring for long-term operation. The machine can find its applications in laminating of PE and nonwoven, laminating of nonwoven and nonwoven, laminating of garment materials and medical use laminating, etc.

Orient Machinery is a specialized coating and laminating line manufacturer in China. We offer a comprehensive range of products, including extrusion coating machine, monofilament extrusion line, barrier film extrusion line, perforated film machine and more.