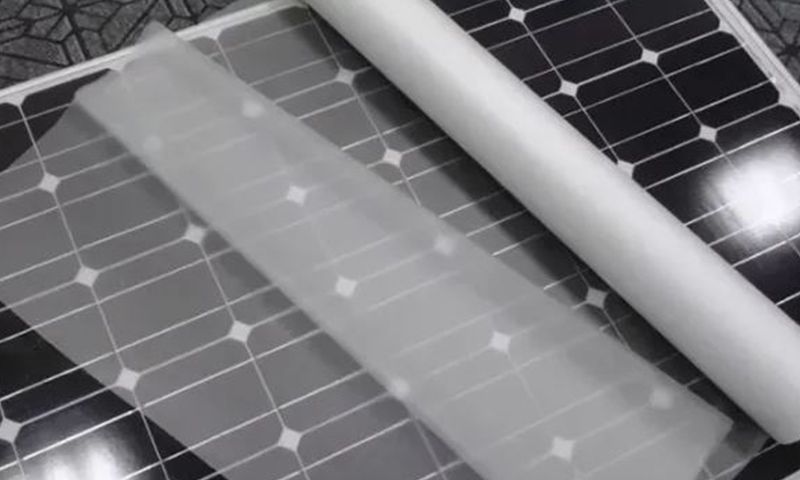

EVA/POE Solar Film Extrusion Line

(Solar EVA/POE Film for PV Cell Encapsulation)

- EVA solar panel encapsulation: used for solar panel encapsulation. Non-sticky at room temperature, easy to handle. The curing and bonding reactions are produced by hot pressing, resulting in a permanent adhesive seal.

- EVA glass interlayer film: used for interior decorative glass interlayer.

- POE solar panel packaging: used for solar panel packaging.

| Model No. | Die Width | Film Width | Film Weight | Line Speed |

| WS160/180-2650 | 2650mm | 2400mm | 0.3-1.0mm | 15m/min |

| WS180/180-3000 | 3000mm | 2750mm | 0.3-1.0mm | 15m/min |

| WS200/200-3000 | 3000mm | 2750mm | 0.3-1.0mm | 15m/min |

* Remarks: Machine dimensions can be customized upon request.

Solar panel encapsulation film extrusion line takes EVA and POE as raw materials. The process includes materials handling, heating, extruding, calendaring, cooling and winding. The production line can be specially made by customer’s requirements. The film product is a new type of thermosetting hot melt film, anti-adhesive at normal temperature, easy for operation. It is fully shaped and adhesive after heating and laminating. It can make the silicon wafer, glass, backplane multi-layer material firmly bonded into the whole one. Excellent heat and humidity resistance, UV resistance, fully realize the long-term use of solar modules in outdoor requirements.

To understand the application of EVA film in solar cells, it is necessary to first understand the structure of the cell. Generally, the cell structure consists of five layers of "glass + EVA + silicon solar cell + EVA + TPT/TPE" from top to bottom. Different structural layers play different functions and roles according to their material characteristics: tempered glass, whose function is to protect the main body of power generation (such as cells), its selection requirements are: high light transmittance (generally more than 91%), ultra-white tempered deal with. EVA film is used to bond and fix the tempered glass and the main body of power generation. The quality of the transparent EVA film directly affects the life of the module. The EVA film exposed to the air is easy to age and turn yellow, thus affecting the light transmittance and power generation of the module. Quality, in addition to the quality of EVA itself, the lamination process of component manufacturers is also very influential. For example, the cross-linking degree of EVA is not up to standard, and the bonding strength of EVA to tempered glass and backplane is not enough, which will cause EVA to age prematurely and affect the service life of components.

- Excellent mixing and plasticizing effect of extruder

- Eliminate thermal stress and solve the problem of thermal shrinkage

- Unique design to solve the problem of sticky layer and peeling of adhesive film